ELEVATOR & ESCALATOR CABLES

CONSTRUCTION OF CABLE

The Cable shall comprise 3 upto and including 24 flexible conductors with nominal cross-section areas from 0.75 mm2to 2.5 mm2

The Annealed bare copper conductor complying with the requirement of BS: 6360. The conductor may tinned as required by customer.

The Insulation consisting of PVC type TI-2 PVC Insulation, complying with the requirement of BS: 6746.

The Sheath consists of PVC type TM2 PVC sheath complying with the requirement of BS: 6746.

The sheath extruded in a single layer on the cores laid parallel.

The Composition of the cable according to the nominal cross-section area of conductors is as follows:

static flexibility test. Tensile strength of strain bearing member.

|

Nominal cross-sectional Area Sq. mm |

Numbers of cores |

|

0.5 |

6, 9, 12, 16, 20 and 24 |

|

0.75 |

6, 9, 12, 16, 20 and 24 |

|

1 |

3, 4, 5, 6, 9 12, 16, 20 and 24 |

|

1.5 |

3, 4, 5, 6, 9 and 12 |

|

2.5 |

3, 4, 5, 6, 9 and 12 |

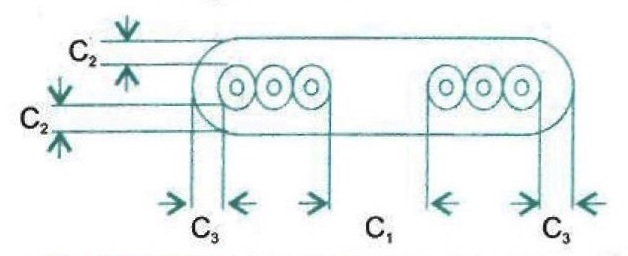

The cores are laid parallel in grouped, closely side by side and covered with sheath comply with the following for cables having the preferred numbers of cores.

MECHANICAL PROPERTIES OF SHEATH

Elongation at break after ageing in air.

Elongation at break before ageing.

Tensile strength after ageing in air

Tensile strength before ageing.

Cold elongation test.

Loss of mass test.

Cold bend test.

|

Conductor |

Radial thickness of insulation |

Thickness of sheath and clearances |

Minimum Insulation resistance at 70'c |

|||

|

nominal cross section area |

maximum diameter of wire |

|||||

|

C-1 |

C-2 |

C-3 |

||||

|

Sq. mm |

mm |

mm |

mm |

mm |

mm |

M£[ /Km |

|

0.5 |

0.21 |

0.5 |

1 |

0.9 |

1.5 |

0.012 |

|

0.75 |

0.21 |

0.6 |

1 |

0.9 |

1.5 |

0.011 |

|

1 |

0.21 |

0.6 |

1 |

0.9 |

1.5 |

0.01 |

|

1.5 |

0.26 |

0.7 |

1 |

1 |

1.5 |

0.01 |

|

2.5 |

0.26 |

0.8 |

1.5 |

1 |

1.8 |

0.009 |

TEST DESCRIPTION

Constructional and dimensional test.

Check on construction.

Measurement of insulation thickness.

Measurement of sheath thickness.

Mechanical properties on insulation.

Tensile strength before ageing.

Elongation at break before ageing.

Tensile strength after ageing in air.

Elongation at break after ageing in air.

Loss of mass test.

Hot pressure test.

Cold bend test.

|

Numbers of cores |

6 |

9 |

12 |

16 |

20 |

24 |

|

Number of Group & Cores in Each Group |

2x3 |

3x3 |

3x4 |

4x4 |

5x4 |

6x4 |

A tearing thread is added inside each core group. It shall be possible to separate the cores without damage to the insulation. Stain-bearing thread of textile material may be included in each core group, replacing one or more cores.